Monday, 3 June 2013

Banbury-based Hanley Precision Tools, a specialist toolmaking company, has upgraded to the latest CNC wire and die sink technology from Sodi-Tech EDM. Among the many improvements in these state-of-the-art machines, the company reports “a quantum leap” in their programming and set-up features, as well as in their overall performance.

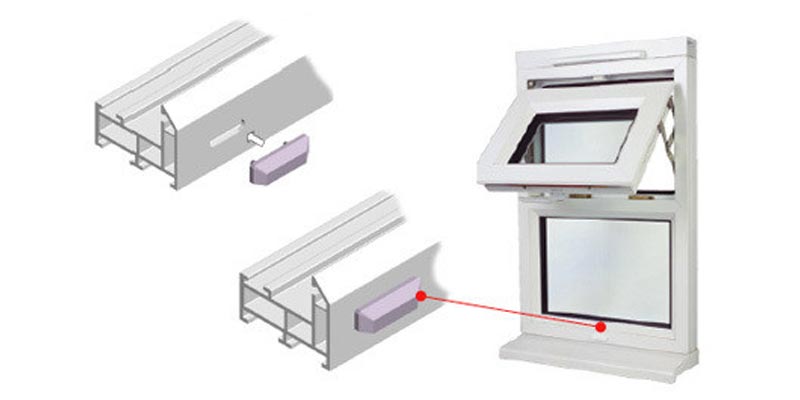

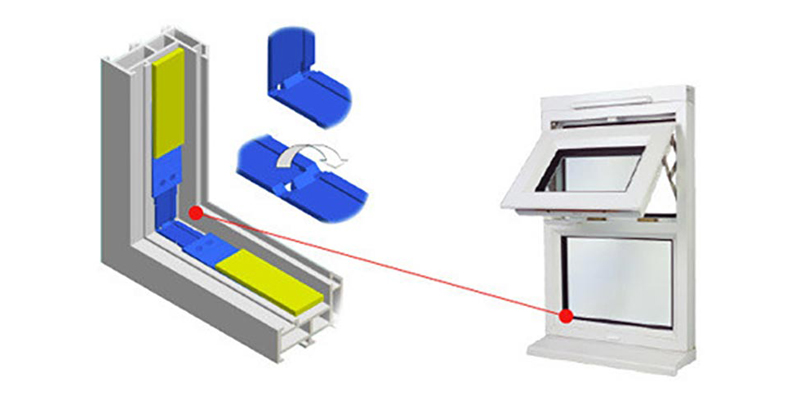

Located side-by-side on the same industrial park, Hanley Precision Tools is closely associated with the Glazpart Group of Companies, with both entities having been founded by owner Ken Hanley. Supplying accessories to the glazing and fenestration industries and the furniture sector, as well as specialised bespoke products to meet specific customer requirements in the medical, automotive, electrical and packaging sectors, the businesses can offer their customers a “cradle to grave” design and manufacturing service.

Glazpart Ltd employs 80 staff at its ISO 9001:2008 certified site, producing millions of mouldings each month. With this in mind, Hanley Precision offers quick and responsive tool making and tool maintenance services.

“We are seeing many customers bringing work back from China, fed up with the logistical challenge of having cash tied up in transit and the poor lead times,” states Glazpart’s Operations Director, Mark O’Mahoney. “Most mould shops cannot afford to operate their own in-house toolroom, which is one of Glazpart’s differentiating benefits. Customers love the fact we have Hanley Precision next door, offering a “one stop shop”.

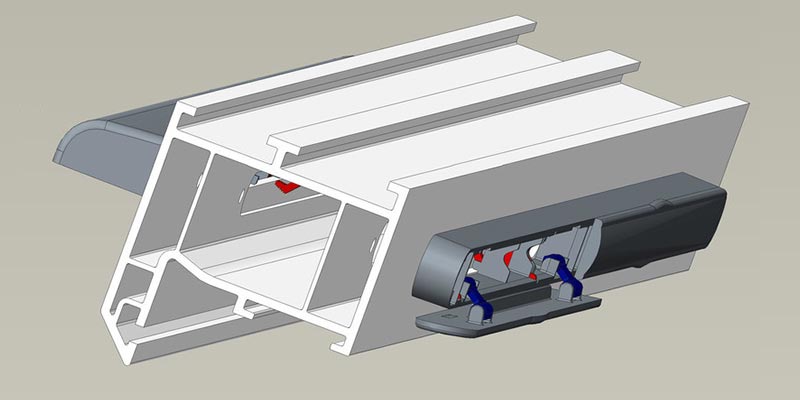

According to Mr O’Mahoney, the clear requirements in terms of EDM capability are speed, precision and reliability, which is why Hanley Precision Tools chose to rely on Sodick technology. As part of a new investment programme, the latest arrivals from Sod-Tech EDM are an AG600L wire EDW and an AG60L die sink EDM. Both are similar in size to the machines that they replaced, but considerably faster and more efficient than their predecessors. “Although they were installed as recently as July 2012, the toolmakers can already see that these new machines represent a real step change,” he says. “The linear drive technology is excellent, while the improvements in speed and reliability are equally impressive.”

The business has been afforded the opportunity to consolidate and optimise its wire and EDM department as a direct result of improved speed and efficiency of the latest Sodick AG600L and AG60L models.

“Programming times are at least 50-60% faster due to in-built default features on the Sodick machines that help accelerate program generation. This is particularly useful when using the wire machine as it means we can produce wire programs for the path of a complex shape in a greatly reduced time. On the die sink we have found that we no longer need to pre-rough cut cavity forms, making the process much faster, whilst finishing is now more refined. We have System 3R technology on both machines for rapid set-up.”

Hanley Precision manufactures tools from materials that include steel, stainless steel and aluminium, including multi-cavity and hot runner system moulds. Moulded parts are produced in every engineering grade plastic, including rigid PVCs. The company is keen to point out that quantity requirements are one of its differentiating features, and is pleased to handle low volume requirements, even one-off if required. Add to toolmaking and production a full design and prototyping service, and the provision of secondary operations such as assembly, printing, foiling, labelling, special Aqua decoration and packaging, and it’s clear that few others can match the comprehensive range of products and services.

“We have seen a lot of investment here in recent times,” says Mr O’Mahoney. “For instance, we have a fully barcode-controlled manufacturing operation – now nothing moves in the factory without being scanned. This helps us control workflow and manage machine capacity.”

Hanley Precision runs its Sodick machines to the limit, filling in any gaps in mouldmaking and mould servicing with precision batch production work on a subcontract basis, often for customers in aerospace and motorsport – the company is located near to several Formula One teams.

“The machines have made us more efficient; more competitive, while we can now run thinner wire, making us more cost effective without any loss of performance. The automatic wire threading capability is also faster and more reliable, which along with a six-station toolchanger on the die sink, means the machines better support our 24-hour operation.”

“The plastics industry is constantly changing and extremely dynamic. You have to be up to speed with your customers’ requirements,” concludes Mr O’Mahoney. “Speed, flexibility, consistency and quality are what determine success. For instance, we have just produced two tools for an OEM customer, from cradle to grave in four weeks – it simply would not have been possible without the new Sodick machines. Ultimately they help us keep our manufacturing costs low.”